The OSR Bioremediation Process

Ohio Soil Recycling utilizes a combination of enhanced bioremediation and mechanically induced volatilization to reduce contaminant constituents in soils and earthen material.

OSR’s enhanced bioremediation process is based on the introduction of specially cultured microbes, protozoa, fungus, algae, and bacteria, as well as oxygen and nutrients to the impacted soils.

For high contaminant concentrations and/or saturated soils, OSR performs an environmentally friendly chemical oxidation process to reduce contaminant levels prior to completion with our bioremediation process.

Step 1: The Micro-organisms

The Microbial Consortia used by OSR contains over 350 different species of microbes, bacteria, protozoa, fungi and algae known to consume or aid in the remediation process.

The Microbial Consortia used by OSR contains over 350 different species of microbes, bacteria, protozoa, fungi and algae known to consume or aid in the remediation process.- Independent microbiology labs are used to provide tested and certified microbial cultures.

- Field studies performed by OSR have identified the best and most effective cultures from over 20 different microbiology labs.

- OSR grows the specifically cultured micro-organisms in poly tanks of water stored in a climate controlled space.

- The micro-organisms are maintained, and reproduction and colonization is driven by “feeding” a proprietary nutrient solution

- Prior to use, the microbial solution is ramped up to contain over 2-billion colony forming units of contaminant degraders.

- White-Rot Fungus

- Grown on wood chip stockpiles

- Secretes an enzyme which weakens the molecular bonds of VOC and SVOC contaminants

- Increases the bio-availability of the contaminant food source

- Mixing the white-rot fungus containing wood chips into the soil assists oxygen content by creating void spaces in the pile

Step 2: Application to Contaminated Soil

Two means of applying micro-organisms to soil:

- Spray Application

- Most even and consistent application

- Results in additional VOC emissions

- Injection Application

- Better for larger quantity projects

- Less equipment intensive

- Lower VOC emissions

OSR primarily uses the spray application approach at our facility due to the more consistent and dependable results provided by this application method. All soils are loaded into a shredder unit to reduce the particle size for even and thorough application of microbes, nutrients, etc. to the soil. Soil additives and microbes are spray applied as the soil moves along a belt system. The OSR application method ensures consistent and timely results through even distribution of remediation products throughout the subject soils and earthen material.

Step 3: Biological Consumption Process

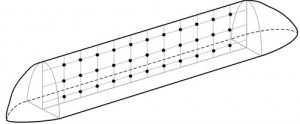

Soils placed in windrows while bio-process takes place

Soils placed in windrows while bio-process takes place- Natural process with carbon dioxide and water as only by-products

- 30-120 day treatment time to clean soil

- Returns soil to clean state acceptable for residential use as defined by Ohio EPA

Step 4: Confirmation Sampling & Analysis

Soil windrow stockpiles are sampled upon completion to confirm clean results

Soil windrow stockpiles are sampled upon completion to confirm clean results- Samples collected in accordance with Ohio EPA and BUSTR guidelines

- At least twice the regulatory required number of samples are collected, and twice the required number of samples are submitted for laboratory analysis to ensure clean results prior to removal from treatment pad.